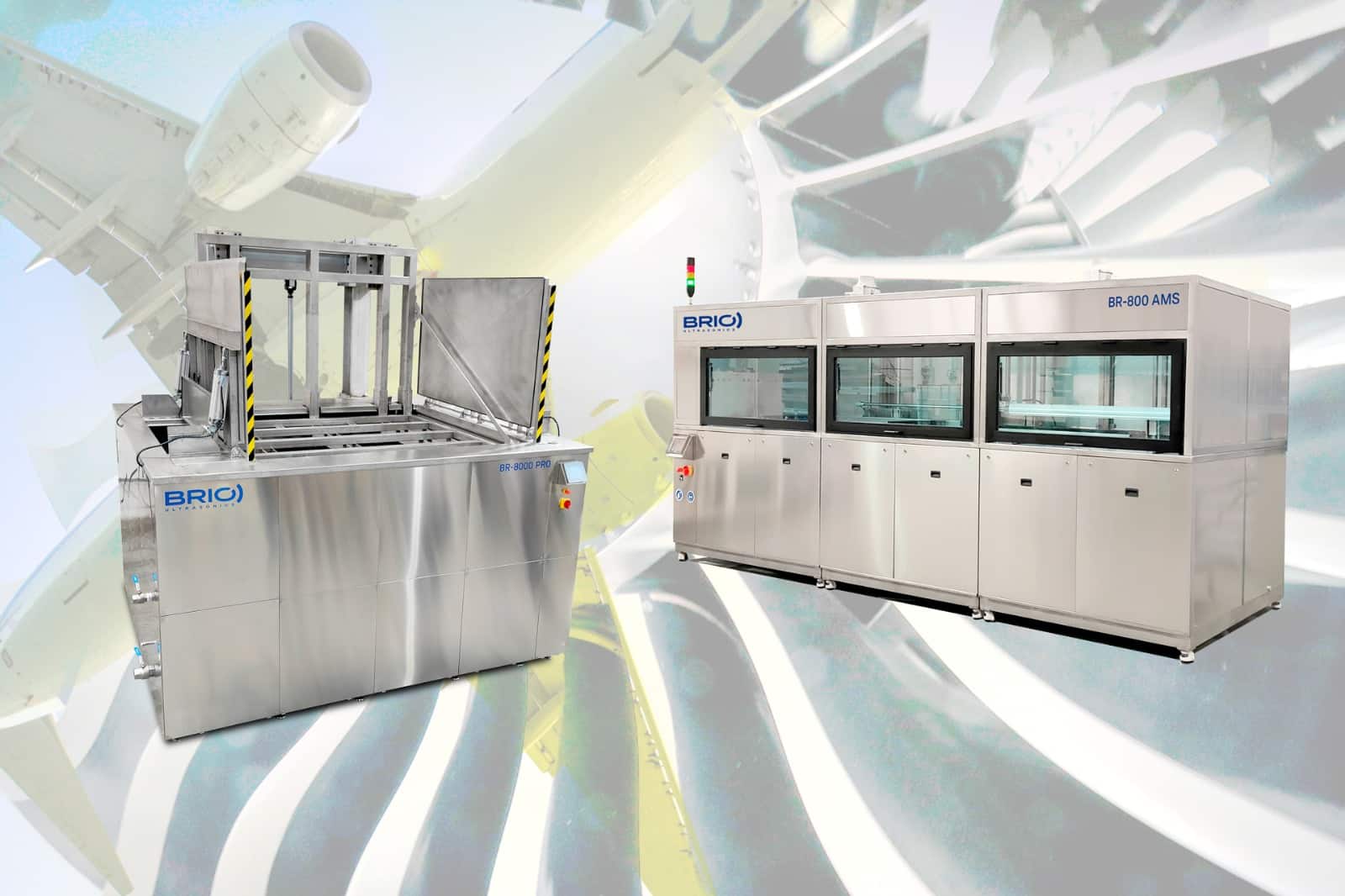

Ultrasound cleaning machines

Ultrasound cleaning is an advanced and highly effective technology for the maintenance and cleaning of industrial parts, molds, surfaces, especially in sectors that require precision and thorough cleaning. This method uses ultrasonic waves to create millions of microbubbles in the cleaning liquid, which, when imploded, generate energy that removes dirt particles, grease and other residues in a deep and efficient manner with micro brushing.

Below, we discuss 5 advantages of Ultrasound cleaning, detailing how this technique not only offers deeper cleaning, but also greater efficiency in the process.

Unparalleled Access to Difficult and Complex Areas

One of the most outstanding benefits of ultrasonic cleaning is its ability to reach hard-to-reach areas. Ultrasonic cavitation allows cleaning bubbles to reach cavities, narrow slots, and holes that would otherwise be impossible to clean using conventional methods.

This unparalleled access is crucial in cleaning parts with complex geometries, such as mold components and delicate mechanical parts, where any residue can affect the functionality or final quality of the product.

Consistency and Precision in Cleaning

Unlike manual techniques, which are often dependent on skill level and can result in an uneven finish, ultrasonic cleaning provides uniform coverage. The ultrasonic waves are evenly distributed in the cleaning fluid, ensuring that the entire part receives the same treatment, regardless of its size or shape. This is essential in high-precision industries such as aerospace or medical, where any trace of contamination or residue can compromise component performance.

Reduction in cleaning time and effort

Another key aspect is the speed of the process. Compared to traditional methods, ultrasonic cleaning allows the process to be completed in minutes, without the need to disassemble complex parts. This not only saves time but also minimises the dependence on manpower, as the process is automated and requires less human intervention. Thus, the time saved on cleaning translates into a faster workflow and greater efficiency in the production chain.

Complete Elimination of Various Contaminants

Ultrasonic technology is effective not only on visible dirt but also on microscopic contaminants such as rust, bacteria, grease and mineral deposits. By adjusting the frequency of the waves and using specific cleaning solutions, it is possible to remove different types of contaminants in a single session. This versatility is essential in sectors such as electronics, where even the smallest impurity can cause component failure, or in the medical industry, which demands high hygiene standards.

Ecological and Sustainable Option - Ultrasonic Cleaning

In addition to being efficient, ultrasonic cleaning is environmentally friendly. This system optimizes water usage and minimizes the need for harsh chemicals, making the process less polluting compared to other cleaning methods. In addition, many ultrasonic equipment are designed to use biodegradable cleaning solutions, reducing the risk of exposure to hazardous chemicals for operators. This feature makes ultrasonic cleaning a sustainable and low-environmental-impact option, which is increasingly valued in today’s industrial context.

Ultrasonic cleaning offers a thorough and efficient solution that covers precision, safety, and sustainability needs in various industries. At BRIO Ultrasonics we develop solutions for all types of needs with the best cleaning ultrasounds.